Structural engineering design services

STRUCTURAL ENGINEERING DESIGN SERVICES

Choose your topic of interest from the list below:

A. General

B. Structural calculations for the USA

C. Structural calculations for Australia

D. How do I know whether a structural calculation is required for a building license

E. Two and three-dimensional structural calculations

F. Overwater building systems

G. Roof structures

H. Foundations

If you do not have the intention to order a wooden prefab house from us but only need engineering services we will be well able and capable to help, support, advise, and prepare a structural calculation.

Prefabworld Bali International provides services and support for all phases of a project from study, planning, and design to preparation of plans and specifications, construction observation, and contract administration. We make an ongoing effort to maintain awareness and understanding of the latest technological trends and concepts so that each client’s needs can be given competent and professional consideration.

The Prefabworld Bali International engineering team is a multidisciplinary team of experts (*), ready to take on turnkey engineering projects of any size, but thriving on the challenges brought by large-scale engineering projects and programs. After more than 15 years in business and many projects delivered, Prefabworld Bali International has built a solid track record as a trustworthy engineering services provider to many clients.

(*) Employing a civil/hydraulic expert, a geotechnical engineer, a coastal engineer, a structural engineer (all university graduates), and an electrical and plumbing engineer (bachelor's degree)

Our structural calculations are prepared with STAAD PRO v8i, a state-of-the-art finite element computer program, fully recognized and accepted by all Counties in the USA and many building authorities worldwide. The structural reports that we submit are based on the results of the computer calculation and include the analyses for maximum allowable deflections, displacements, forces, and stresses per ASCE, ACI, AASHTO, AITC, or any other USA code. Our reports are detailed and normally approved by the building authorities without a hitch.

The calculations for our wooden house structures may be extended with a calculation for the foundation.

The costs for the preparation of a structural calculation are not included in the price for the house, since any client may engage a local engineer. We would be happy to submit a quotation for the structural design.

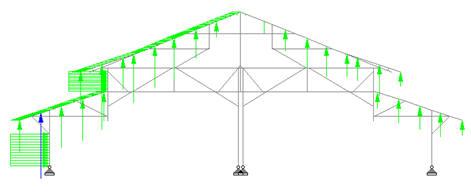

TWO AND THREE-DIMENSIONAL STRUCTURAL CALCULATIONS

![]()

![]()

2-dimensional 3-dimensional

Our structural calculations are prepared with STAAD PRO v8i, a state-of-the-art finite element computer program (FEM), fully recognized and accepted by all Counties in the USA and many building authorities worldwide. The program can analyze both 2- 2-dimensional and 3- 3-dimensional structures. The structural analysis reports that we submit are based on the results of the computer calculations and include the analyses for maximum allowable deflections, displacements, forces, and stresses by ASCE, ACI, AASHTO, AITC, or any other USA code. Our reports are detailed and normally approved by the building authorities without a hitch.

The calculations for our wooden house structures may be extended with a calculation for the foundation.

The costs for the preparation of a structural calculation are not included in the price for the house, since any client may engage a local engineer. We would be happy to submit a quotation for the structural design.

STRUCTURAL CALCULATIONS FOR THE USA

The Counties in the USA now require that not only detailed drawings be submitted but also a structural calculation shall be submitted to complete the set of documents to apply for a building license for a dwelling of any size that has been prefabricated outside the USA. While some Counties on the mainland may be lenient as to the requirement of such structural calculation, all Hawaiian Counties strictly adhere to this regulation. Our company can produce the calculation in compliance with the latest USA codes (IBC 2018) including the amendments which may differ from County to County. Our wood connections will all be analyzed and calculated by applying the NDS 2015 (National Design Specification for wood construction).

For customers wanting to build their house in Hawaii, many may require the services of a registered architect and structural engineer. These professionals can assist owners in meeting the requirements of the city or county building department having jurisdiction over the project site. Their services may include a review of our drawings, structural calculation reviews, foundation design reviews, lateral load resistant design assessment, and preparation of plans for building permit approval. In such cases, we work together with David Rockwood, Architect and Associate Professor at, the University of Hawaii at Manoa, and Professional Engineer and Professor Ian Robertson, University of Hawaii at Manoa. We would be happy to offer a referral to customers seeking such services. Both persons will also advise us about any other area in the USA (mainland and other islands).

STRUCTURAL CALCULATIONS FOR AUSTRALIA

Structures erected in Australia require a structural certificate. Regardless of whether it is designed by an architect or homeowner, a structural certificate must be obtained from a registered structural engineer. This forms part of the Building Permit application. Our company's professional structural engineering is deemed to comply with Australian building regulations.

We recommend, however, that before purchasing one of our units to consult building certifiers (County) in your local area to address specific requirements of the proposed building site and local building regulations.

STRUCTURAL CALCULATIONS FOR THE CARIBBEAN & PACIFIC

A new and upcoming trend is that the Caribbean and Pacific islands will require a structural calculation for a wooden prefab house. This is mainly based on the effect of global warming, whereas hurricanes and typhoons will occur more frequently in the coming decade and will strike with much higher wind forces.

HOW DO I KNOW IF A STRUCTURAL CALCULATION IS REQUIRED FOR A BUILDING LICENCE

We strongly advise you to contact your local Building Authority to find out whether an imported wooden prefab house shall comply with the local building codes and requirements and comply with special import regulations. The size of the house may be a determining factor, If a structural analysis needs to be submitted you may ask the following questions:

- Would it be acceptable if the wooden prefab house complies with the IBC 2009 (USA International Building Code 2018)? If the answer is affirmative we will be able to supply, however, if the answer is negative and the house shall comply with the local building codes we may not be able to supply unless you engage a local engineer to cooperate with us.

- Are there restrictions on the use of particular hardwoods originating from Indonesia? If the answer is yes you need to find out which wood species are prohibited.

- Shall the wood be FSC Certified? The answer is NO. However, the wood needs to comply with the V-legal system. This V-legal system is an Indonesian legal document fully adopted by the FSC. Complying with the V-legal system will allow you to import any wooden house from Indonesia since not one supplier in Indonesia has an FSC Certificate in place with a chain of custody to the first supplier; the felling concession.

Read more about the V-legal system < here >

FOR THOSE WHO WANT TO KNOW IN DETAIL ABOUT FOUNDATIONS AND OVERWATER BUILDING

Our senior in-house Civil/Hydraulic and Geotechnical engineer with 50 years of International experience under his belt, - in particular with the over-water building technique -, may help and advise you on the required piling type, piling depth, and superstructure. To safely determine the pile capacities one needs to take into account the pile's end bearing capacity + negative or positive friction along the pile shaft. This will define the safe pile driving depth. Waves have a minor influence on piles, however, it needs to be investigated if wave run-up caused by cyclones needs a special superstructure. We will prepare a wave propagation calculation to assess this. Our company would be happy to prepare a quotation for (*) the engineering works for your overwater project, even if you do not order one of our units. Pile structures can be made from either concrete, steel, or wood. The latter being the cheapest.

(*) We will issue a Memorandum of Understanding (MOU) first. Once the parties have agreed on this MOU we will commence the engineering works.

A. Piling depth

Our company has developed a special system and technique to have our models safely built over water, either in lakes or coastal waters. Our senior in-house Civil/Hydraulic and Geotechnical engineer with 50 years of International experience under his belt may help and advise you on the required piling, piling depth, and superstructure. To safely determine the pile capacities one needs to take into account the pile's end bearing capacity + negative or positive friction along the pile shaft. This will define the safe pile driving depth. Waves have a minor influence on piles, however, it needs to be investigated if wave run-up caused by cyclones needs a special superstructure. Our company would be happy to prepare a quotation for the engineering works for your overwater project, even if you do not order one of our units. Pile structures can be made from either concrete, steel, or wood. The latter being the cheapest.

You may also request us to prepare a free-of-charge ballpark volume estimate for your over-water project. To this end, we need data such as the seabed subsoil configuration (sand, clay, coral, rock. or a combination thereof), the water depth, and the type of house that will sit on the pile structure. We can only provide a general Bill of Quantities (volume estimate). Unfortunately, we are unable to make a cost estimate since we do not know the prices of materials (piles, concrete, etc) in your area. You need to inquire about the prices by yourself based on our BOQ to acquire a ballpark cost figure.

B. Timber piles

Properly employed timber marine piles are a long-term, low-cost, environmentally sustainable solution. They do not corrode and proper treatment protects them from environmental degradation mechanisms such as marine borers and rot. They do not require expensive cathodic protection systems or expensive coating systems to provide them with adequate service life, but they will benefit from a wrap or a PVC tube encasement between the mud line and the high tide mark. If this is done the piles will outlast their counterparts with low initial cost, very low ongoing maintenance costs, and will last for > 50 years.

Piles below the mud line will not decay or be attacked by marine borers. Above the mud line and below the high tide mark (splash zone) they are susceptible to various levels of marine borer attack. This is generally classified by various standards as a high hazard in salt water (coastal and some saltwater rivers). In these waters, we recommend a treat with a special wrap. Such treatment protects the timber from all kinds of marine borers such as the most dangerous shipworm (Toredo, Bankia), the less dangerous gribble, piddocks, pill-bucks, and more.

C. Concrete and steel pipe piles

Nowadays most of the piling designs for overwater structures define concrete or steel pipe piles (open or closed at the bottom), connected at the top by concrete capping beams. Such structures will not be affected by marine borers and/or rot, however, steel pipe piles need to be protected by concrete collars extending from the bottom of the capping beams to below the splash zone to protect the piles from corrosion. In addition, often a cathodic protection system is added. The surfaces of the submerged steel pipe piles are often extra-protected with a coal tar epoxy resin treatment.

Concrete exposed to seawater is wetted by a solution of salts, principally sodium chloride and magnesium sulfate. Damage to concrete, if it occurs, usually results from failure to use good practices in concrete construction. Magnesium sulfate may attack most, if not all, of the constituents of hardened Portland cement paste, especially the aluminate constituent; chlorides may promote corrosion of steel; alkalies may participate in alkali-aggregate reactions. Thus, concrete exposed to seawater should be made with cement of controlled aluminate content and with nonreactive aggregate, embedded steel should be well covered (higher than normal practice) by concrete of low permeability, and good construction practices should be followed.

NOTE: If you will not order an overwater unit from us but only need the design for the overwater substructure + piles, let us know via our contact form. Our senior civil/hydraulic engineer would be happy to help and advise.

In engineering, a foundation is the element of a structure that connects it to the ground or more rarely water, transferring loads from the structure to the ground. Foundations are generally considered either shallow or deep. Foundation engineering is the application of soil mechanics and rock mechanics (geotechnical engineering, refer to < soil investigation > ) in the design of foundation elements of structures.

Foundations provide the structure's stability from the ground:

♠ To distribute the weight of the structure over a large area to avoid overloading the underlying soil (possibly causing unequal settlement),

♠ To anchor the structure against natural forces including earthquakes, floods, droughts, frost heaves, tornadoes, and wind,

♠ To provide a level surface for construction,

♠ To anchor the structure deeply into the ground, increasing its stability and preventing overloading,

♠ To prevent lateral movements of the supported structure.

Requirements of a proper foundation.are based on the design and the construction of a well-performing foundation and must possess some basic requirements, viz:

♠ The design and the construction of the foundation are done such that it can sustain as well as transmit the dead and the imposed loads to the soil. This transfer has to be carried out without resulting in any form of settlement that can cause stability issues for the structure,

♠ Differential settlements can be avoided by having a rigid base for the foundation. These issues are more pronounced in areas where the superimposed loads are not uniform,

♠ Based on the soil investigation results, it may be recommended to have a deeper foundation to guard against any damage or distress. These requirements are mainly caused due to the problem of shrinkage and swelling due to temperature changes,

♠ The location of the foundation chosen must be an area that is not affected or influenced by future works or factors.

We will discuss the following types of foundations (C; click on a yellow link to go straight to the topic of your choice).

A. Shallow footing foundations

B. Pile foundations

C. Slab foundations

D. Strip foundations

E. Retaining walls

F. Foundations on soft soils

G Floating foundations

H. Engineering report

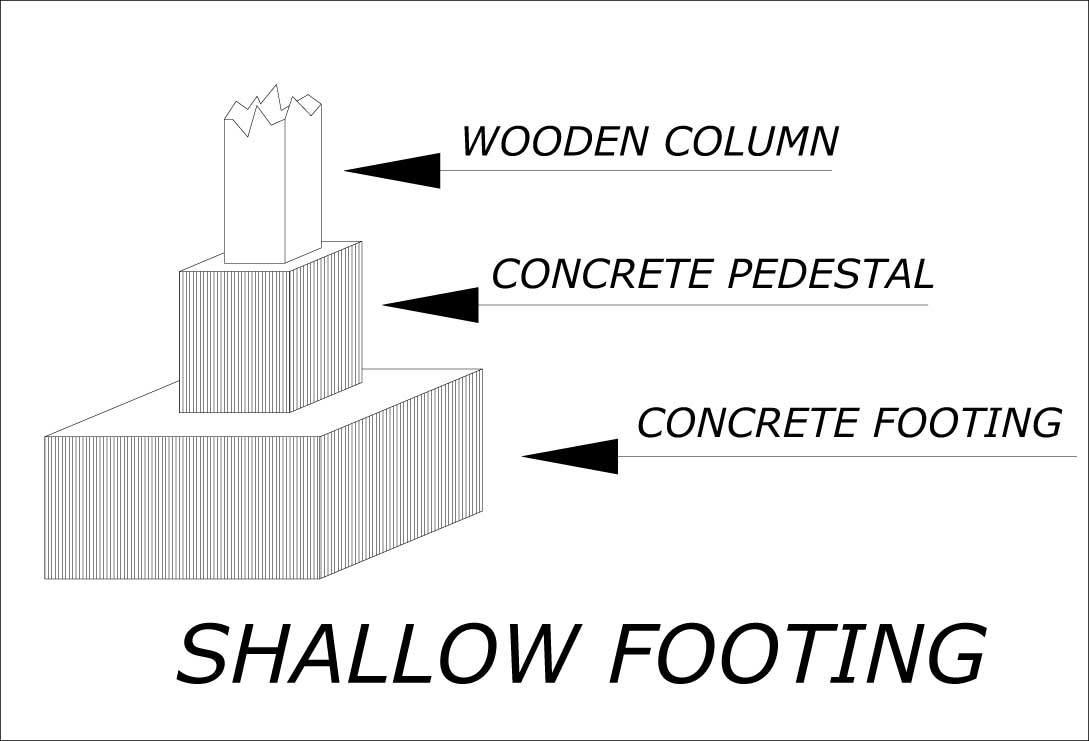

SHALLOW FOOTING FOUNDATIONS

A shallow foundation is a type of building foundation that transfers structural load to the earth very near the surface, rather than to a subsurface layer or a range of depths, as does a deep foundation. Customarily, a shallow foundation is considered as such when the width of the entire foundation is greater than its depth. In comparison to deep foundations, shallow foundations are less technical, thus making them more economical and the most widely used for relatively light structures. This type of foundation is most often recommended or used by us.

A Pile foundation, a kind of deep foundation, can be defined as a slender column or long cylinder made of materials such as concrete steel, or sometimes timber which are used to support the structure and transfer the load at the desired depth either by end bearing or skin friction.

Foundation piles are usually used for large structures and in situations where the soil at shallow depth is not suitable to resist the bearing capacity, excessive settlement, resist uplift, etc. A pile foundation is often an expensive option

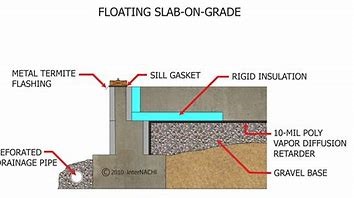

Slab-on-grade or floating slab foundations are a structural engineering practice whereby the concrete slab serves as the foundation for the structure and is formed from a mold set into the ground. The concrete is then placed into the mold, leaving no space between the ground and the structure. This type of construction is most often seen in warmer climates, where ground freezing and thawing are less of a concern and where there is no need for heat ducting underneath the floor. ]

Slab-on-grade foundations are commonly used in areas with expansive clay soil. While elevated structural slabs perform better on expansive clays, it is generally accepted by the engineering community that slab-on-grade foundations offer the greatest cost-to-performance ratio.

A strip foundation (or strip footings) is a type of shallow foundation that is used to provide a continuous, level (or sometimes stepped) strip of support for linear structures such as walls or closely spaced rows of columns that are built on top of the foundation, placed centrally along their length.

Strip foundations are most suitable where the soil is of relatively good bearing capacity. They are particularly suited to light structural loadings such as those found in many low-rise or medium-rise domestic buildings In other situations.

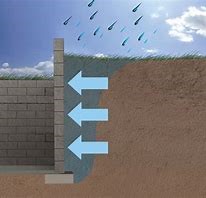

A retaining wall is designed to hold in place a mass of earth or the like, such as the edge of a terrace or excavation. The structure is constructed to resist the lateral pressure of soil when there is a desired change in ground elevation that exceeds the angle of repose of the soil.

Every retaining wall supports a "wedge" of soil. The wedge is defined as the soil that extends beyond the failure plane of the soil type present at the wall site and can be calculated once the soil friction angle is known to refer to < soil investigation >. As the setback of the wall increases, the size of the sliding wedge is reduced. This reduction lowers the pressure on the retaining wall.

The most important consideration in the proper design and installation of retaining walls is to recognize and counteract the tendency of the retained material to move downslope due to gravity. This creates lateral earth pressure behind the wall which depends on the angle of internal friction (phi) and the cohesive strength (c) of the retained material, as well as the direction and magnitude of movement the retaining structure undergoes.

Lateral earth pressures are zero at the top of the wall and – inhomogeneous ground – increases proportionally to a maximum value at the lowest depth. Earth pressures will push the wall forward or overturn it if not properly addressed. Also, any groundwater behind the wall that is not dissipated by a drainage system causes hydrostatic pressure on the wall.

Lateral earth pressures are zero at the top of the wall and – inhomogeneous ground – increases proportionally to a maximum value at the lowest depth. Earth pressures will push the wall forward or overturn it if not properly addressed. Also, any groundwater behind the wall that is not dissipated by a drainage system causes hydrostatic pressure on the wall.

It is important to have proper drainage behind the wall to limit the pressure on the wall's design value. Drainage materials will reduce or eliminate the hydrostatic pressure and improve the stability of the material behind the wall.

As an example, the International Building Code requires retaining walls to be designed to ensure stability against overturning, sliding, excessive foundation pressure, and water uplift; and that they are designed for a safety factor of 1.5 against lateral sliding and overturning.

Retaining walls can be made from rock, brick, timber, and reinforced concrete, Below we show some small retaining walls. We can design much bigger structures if required.

The magnitude of the settlement and the appropriate settlement prediction play an important role in preventing structural damage to newly erected buildings.

Most notorious are soft clay layers to build on. Clay is a type of soil that is made up of very tiny particles. This means that clay can soak up a huge amount of water and then hold onto the moisture. When clay becomes wet, it expands, becoming slippery and pliable. During long periods of dry weather, the clay dries out, hardens, and shrinks significantly.

These extreme changes in the amount of space clay takes up can cause significant shifts in foundations, which can damage the buildings on top of them. To avoid instability in your new construction project over the long term, you must take into account the soil type on your site and take action to prevent clay’s expansion and contraction from damaging your building’s foundations. To detect whether soft clay layers are present and at which depth at your build site a soil investigation is highly recommended (refer to < soil investigation >.

The simplest way to build stable foundations on soft clay is simply to dig deeper to find firm ground. This approach makes it possible to build a standard footing or strip foundation that rests on stable ground, which should help to prevent subsidence and other issues traditionally associated with clay soils.

Building wider foundations is another good option when building on clay soil. Expanding the lateral size of the foundations spreads the pressure exerted by swelling clay over a much larger area.

Soft clay shrinking

G. FLOATING FOUNDATIONS

A floating foundation consists of boxlike rigid structures set at such a depth below ground that the weight of the soil removed to place it equals the weight of the building; thus, once the building is completed, the soil under it will bear the same weight. It makes the building like a boat that obeys Archimedes’ principle—it is buoyed up by the weight of the earth displaced in creating the foundation. Floating foundations consist of flat reinforced concrete slabs or reinforced concrete tubs with walls turned up.

Floating foundation

An engineering report is a key form of written communication that is a direct reflection of the company's knowledge of a particular subject. Engineering reports present facts and conclusions about our designs. Typically, an engineering report includes research about technical concepts as well as graphical depictions of designs and data. An engineering report also follows a strict organization. This way, when other people read what we write, they can quickly locate the information that interests them the most

The engineering report indicates why we chose a certain design option with detailed background information on the choice, such as data from a geotechnical investigation, a topographic survey, and particular design boundary conditions.